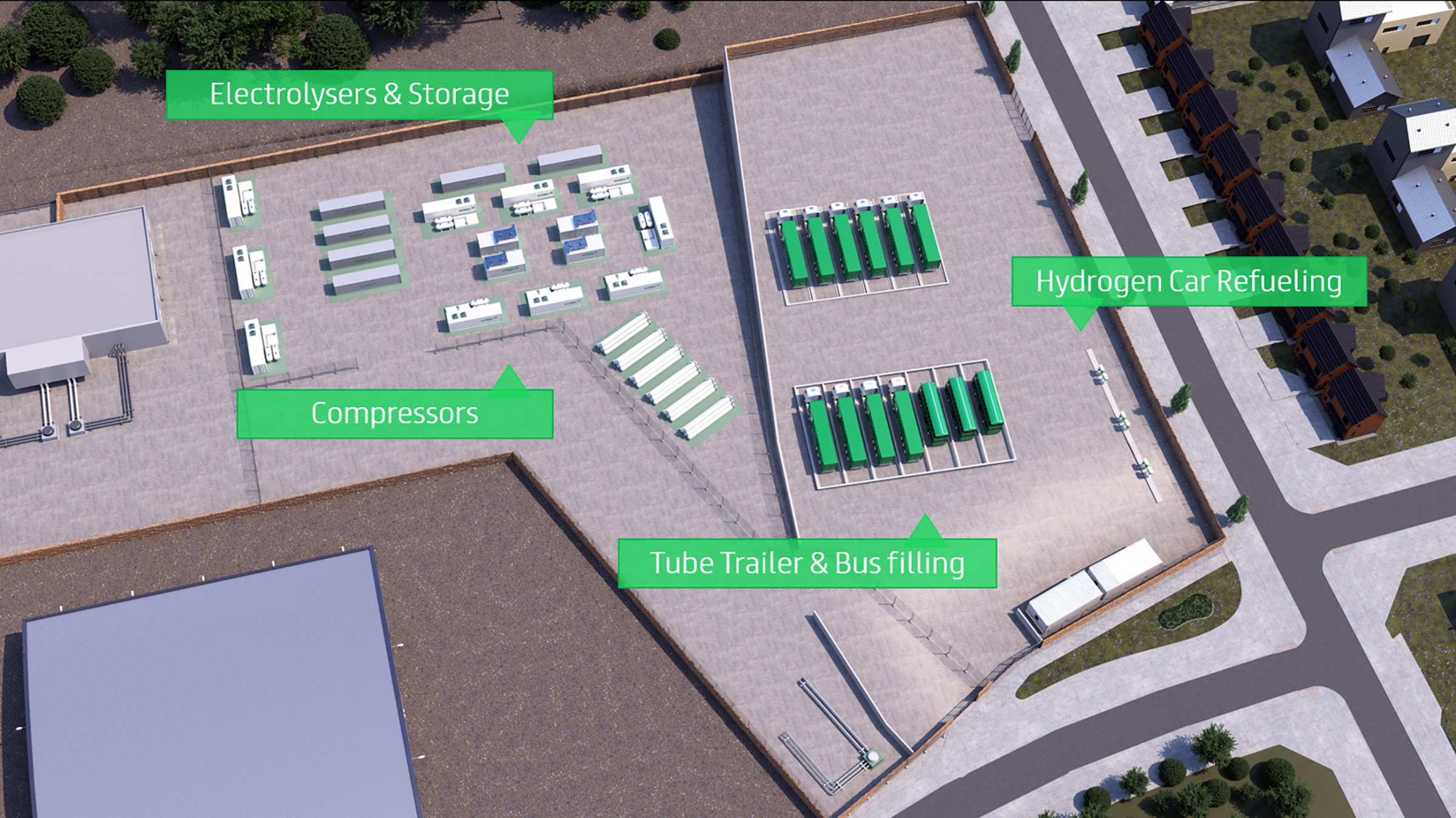

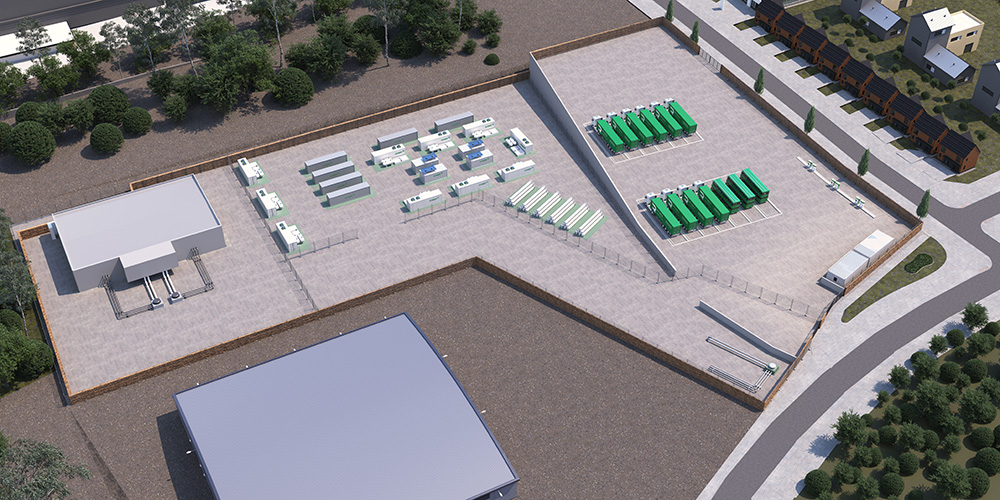

Hygen and N-Gen are delighted to be working together to deliver a state-of-the-art low carbon hydrogen production facility in east Bradford, off Bowling Back Lane. The development will be built on the Northern Gas Network (NGN) Birkshall gas storage site in Bradford. It will deliver one of the UK’s largest low carbon hydrogen production facilities with the aim of using renewable energy to produce hydrogen.

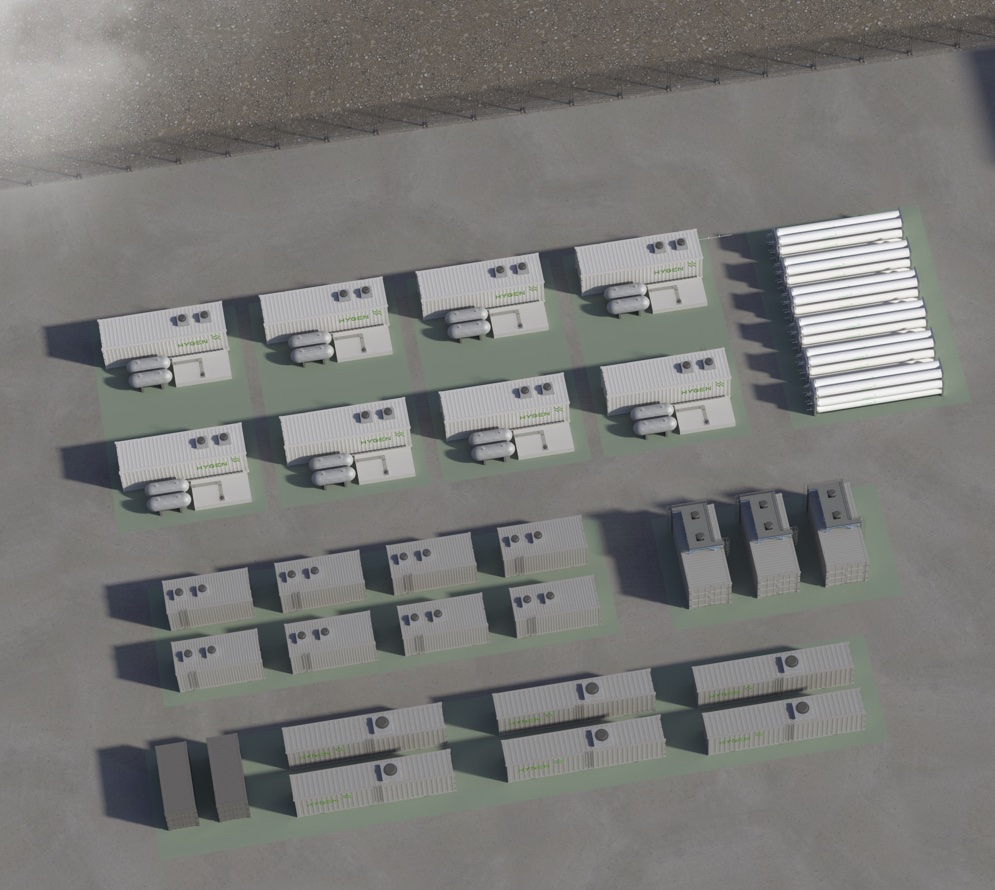

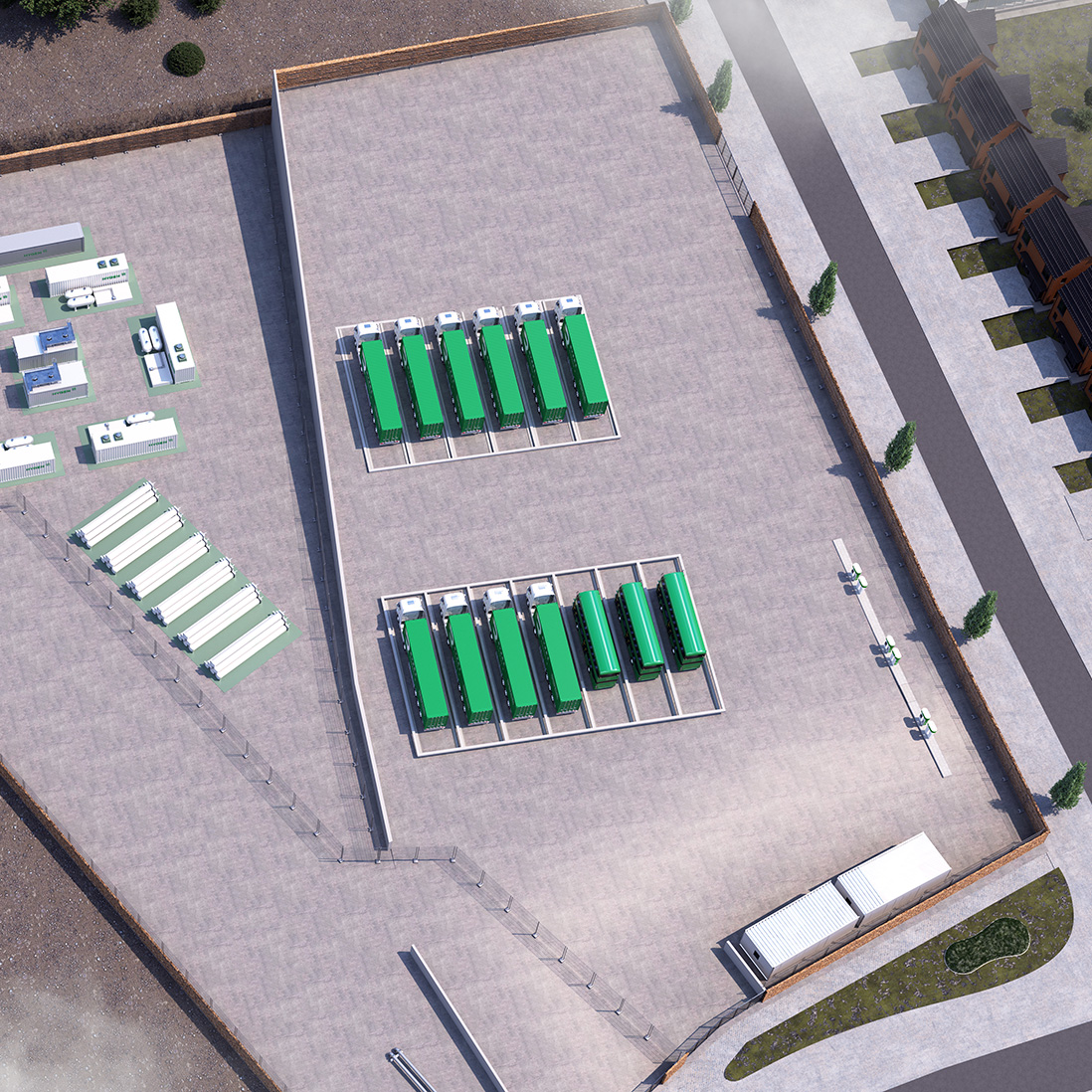

Once built, the facility will include a production facility to generate hydrogen from low carbon energy sources and a hydrogen refuelling station for local industry, buses and public and private sector fleets. The site could achieve the decarbonisation equivalent of removing 800 diesel-fuelled buses a day from the roads in West Yorkshire.

The refuelling facility will benefit the people of Bradford and the wider community with lower carbon emissions in the area contributing towards improving the air quality and contributing towards UK’s carbon reduction commitments made at COP26.

The project is significant for Bradford’s future economic growth plans, which could end up being worth £900m and create over 9,000 high-quality jobs by 2030.

Hygen Energy Ltd is part of HydraB, the group holding company of a number of ‘Road to Zero’ companies inspired by Jo Bamford. These include: Wrightbus (world’s first Hydrogen powered double decker bus and world’s most efficient double decker battery electric bus); Ryze Hydrogen which distributes hydrogen to fleet users and industrial customers, and Fuze Finance which offers innovative leasing/TCO contracts for zero-emission vehicle fleets.

Hygen is a company focused on the building of low-carbon hydrogen production sites. It is targeting more than 500MW of low-carbon hydrogen production projects across the UK. All of the projects Hygen delivers have an identified customer for a significant percentage of the hydrogen produced.

- An opportunity to share the latest proposals with the community

- Gather community feedback and comments, including on future consultation and early project proposals

- Consult with you prior to submission of the formal planning application

- Answer your questions and identify issues most important to you

- Discuss the project benefits and potential community investment fund

We intend to submit a planning application for the green hydrogen production facility in 2023.

N-Gen is an energy developer committed to working with clients to identify and provide end-to-end energy solutions required for decarbonisation. Working across the upstream and midstream sectors, it aims to produce 75MW of green and low carbon hydrogen by 2025, along with all supporting infrastructure.